Time:2025-10-21 Views:1

The maintenance and repair of energy storage batteries are critical for ensuring their long - term reliability, safety, and optimal performance. As energy storage systems become more prevalent in various sectors, including electric vehicles, renewable energy integration, and grid - scale applications, effective maintenance and repair technologies have emerged as a key area of focus.

One of the fundamental aspects of energy storage battery maintenance is regular inspection. This involves visual checks for physical damage, such as cracks in the battery casing or signs of corrosion on terminals. In addition, non - destructive testing methods, like ultrasonic imaging, are used to detect internal defects without disassembling the battery. These inspections help identify potential issues at an early stage, preventing more severe failures and costly repairs.

Battery management system (BMS) calibration and optimization are also essential maintenance tasks. The BMS monitors and controls the battery's charging, discharging, and overall health. Regular calibration ensures that the BMS accurately measures parameters such as voltage, current, and temperature, enabling precise control over the battery's operation. Advanced diagnostic tools are used to analyze BMS data, detect anomalies, and perform necessary adjustments to optimize battery performance and extend its lifespan.

When it comes to repair, techniques vary depending on the type of battery and the nature of the fault. For lithium - ion batteries, which are widely used in energy storage, cell balancing is a common repair procedure. Uneven charging or discharging of cells can lead to performance degradation and reduced cycle life. Cell balancing equalizes the charge levels among cells, restoring the battery's overall efficiency. In cases of more severe damage, such as internal short - circuits or electrolyte leakage, specialized repair methods are required, often involving the replacement of faulty components. These may include replacing individual cells, electrodes, or the electrolyte itself.

Moreover, predictive maintenance technologies are increasingly being adopted in the energy storage battery industry. By using machine learning algorithms to analyze historical data on battery performance, these technologies can predict potential failures and recommend maintenance actions in advance. This proactive approach minimizes downtime, reduces maintenance costs, and enhances the overall reliability of energy storage systems.

Read recommendations:

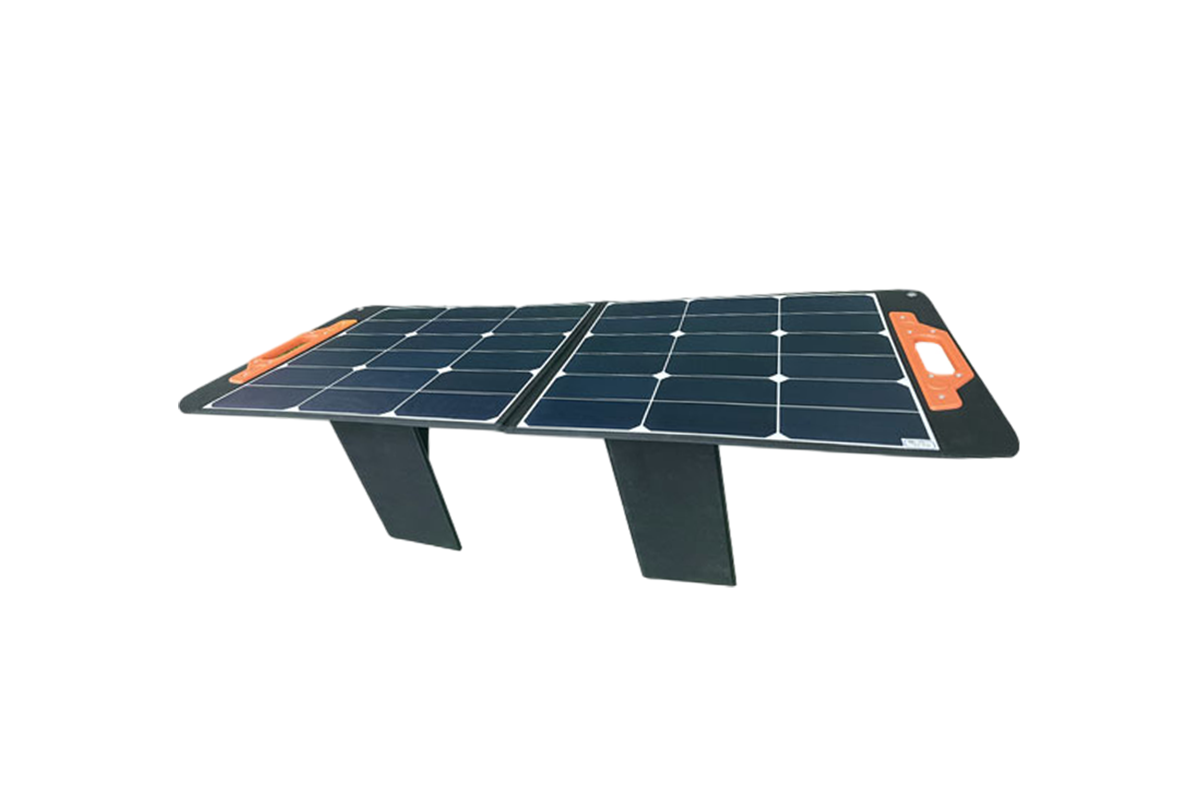

Solar Panels 100W better wholesale